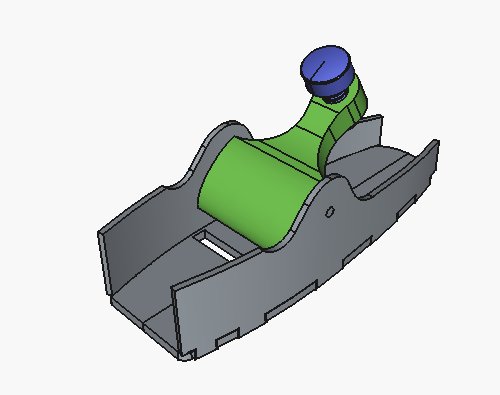

Flushing the bed and mouth

With the infills now temporarily pinned in place I turned to one of the most consequential internal operations on the plane: bringing the wooden bed into perfect continuity with the steel at the mouth. This step is not about appearance, with the blade in place none of this work will be visible. Any bump, hollow, or discontinuity here will telegraph directly into blade support, so the goal is a single, uninterrupted bearing surface from the rear of the bed through the mouth. That's the theory anyway, in reality getting 70% of the surface co-planar will be a win. I used dry erase marker on the iron itself to read contact, working slowly and deliberately to remove only the high spots in the wood. The process is highly repetitive: each pass shows not just where material needs to come off, but how the bed and shell are relating to one another as an assembled system.

What I was looking for was consistency rather than speed. Uniform contact across the width of the iron and right up to the mouth, without biasing the shell or closing the mouth even slightly. This is one of those operations where progress is measured in feel and witness marks rather than visible change, and it rewards restraint. I'm aiming for ~70% of the surface to bear with a preference for the surfaces immediately around the mouth. I'm getting there, probably 40-50% right now, but with the gaps that exist near the mouth. I did some testing with feeler gauges, and it's about a .002 gap right now between the metal at the mouth and the back of the blade.

Once I get that gap closed, the remaining interior steel can be brought up to final finish, after which the infills will be permanently locked in place.